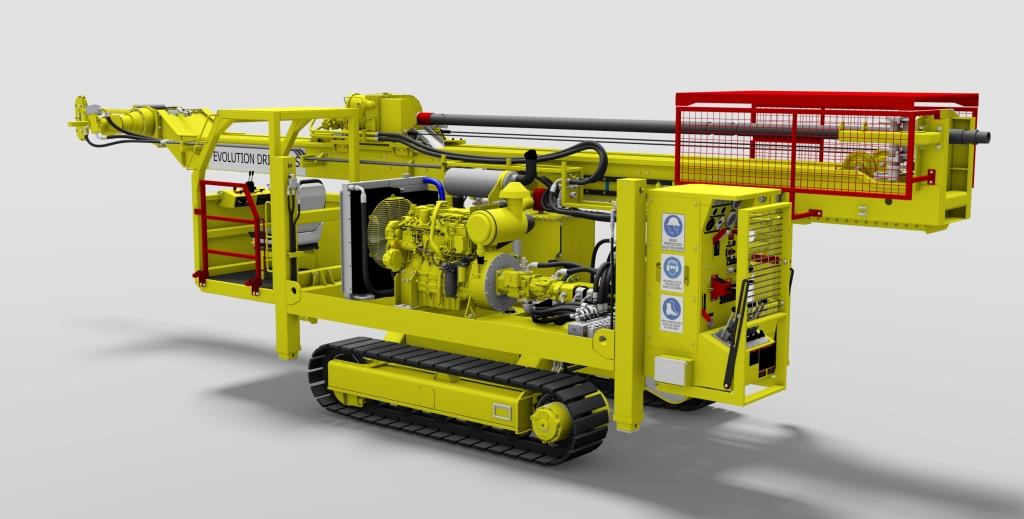

The FH1000 model is the smallest of the FH series Drill Rigs. This rig is a small yet powerful design, which is available in either truck or crawler mount.

Products by Evolution Drill Rigs

FH1000

- Specifications & Features

Evolution Drill Rigs announces the release of the FH1000, its newest addition to its range of multi-purpose surface drills. Of particular importance to EDR was to produce a machine with operational features and versatility, not currently available in the market. This has been achieved while maintaining an economical outcome. This powerful top head drive is available in either 3.9 or 6.9 M head stroke. Its hydraulic system has been based on the proven designs of the larger EDR drills and incorporates the same high quality componentry. The rotation head high torque low gear ratio allow for a stable rotation speed and fitment of an RC system. The rotation head helical gear train shares mostly common componentry with the larger FH1300. This allows for a robust design combined with quiet operation. These gearbox’s are designed in house by Evolution. Traverse is achieved using a cable over sheave system. A design objective was to achieve a smooth fine feed rate and improve service life of the head slides. This required high end material selection and reducing carriage slide contact loading with the mast.

- Engineering Design

Experienced design engineers with many years drilling equipment experience. Designed to meet or exceed the relevant Australian and International Standards. Finite Element Analysis (FEA) of all components in the critical load path. Design verification via 3rd party design consultants. Designed to meet the requirements of MDG15 and MDG41.

- Safety & Environment

Safety has been a driver for this project with the design based on compliance with the Australian guidelines of MDG15 and the ISO standard EN16228-1&2 ‘Drilling and foundation equipment-Safety’. EDR decided to top mount the winch and fit as standard a failsafe winch overwind protection system. Hydraulic levers for set up and track drive are either interlocked or lockable to avoid accidental operation. The drill deck layout has been designed with maintenance accessibility a priority. Critical to achieving this was the top mount main winch and single cooler package. This allowed for better placement of components and hose routing around the deck. A single rear mast stay removes the need for deck access during rig set up.

- Specifications

DEPTH CAPACITY

• NQ Core 1150 meters

• HQ Core 786 meters

• HWT Core 518 meters

• RC 4": 198 meters (nominal)

ENGINE

• John Deer Power Tech 6.8L 155kW (208Hp)-(Opt 1)

• Caterpillar C6.6 ACERT (Opt 2)

• Cummins B5.9-173 (Opt 3)

PULL BACK

• 97 kN (21,783 lbf)

PULLDOWN

• 45 kN (10,116 lbf)

TRAVERSE SPEED (ROTATION HEAD)

• Up - 47 m/min (154 ft/min)

• Down - 30 m/min (98 ft/min)

ROTATION HEAD

• Top Head Drive

• Maximum Torque 5965 Nm (4400 ft/lb) in low gear

• 0 - 1500 Rpm speed range

• Two Speed Gearbox

• 100% Theoretical

MAIN WINCH

• 88.4 kN (19,870 lbf) Maximum pull

• 55 M/min (180 ft/min)

• Mast Top Mounted

• 1 x Multi disc brake unit, Fail safe spring

activated, Hydraulic pressure release

• Main winch rope, safety factor to meet BS/EN791)

• 6 meter rod pull capacity

WIRELINE WINCH

• Deck Mounted

• 13.5 kN (3044 lbf) Maximum Pull

• Rope capacity 1400 meters x 6mm rope

• 342 M/min (1124 ft/min) Maximum Speed

WATER PUMP

• Standard FMC W1122BCD 140Lpm @1000Psi

FH1300

The FH1300 is available in a range of configurations including truck or crawler mounted and can be fitted with an onboard air compressor up to 1150/500.

- Specifications & Features

The FH1300 multi-purpose drill has been developed to cater for the increasing depths required for Greenfields Mineral Exploration and Coal drilling programs using core, rotary air or mud and reverse circulation drilling programs. The FH1300 is available in a range of configurations including truck or crawler mounted and can be fitted with an onboard air compressor up to 1150/500.

- Engineering Design

Experienced design engineers with many years drilling equipment experience. Designed to meet or exceed the relevant Australian and International Standards. Finite Element Analysis (FEA) of all components in the critical load path. Design verification via 3rd party design consultants. Designed to meet the requirements of MDG15 and MDG41.Main Winch Travel limiting system to prevent overwinding the hoist plug. Wireline winch safety stop system to automatically stop the wireline winch when the over shot reaches a predetermined point. Rod Spin guard with rotation interlock to protect the drill crew from the spinning drill rod. Optional onboard Air Compressor with up to 1150/500 capacity.

- Safety & Environment

Latest generation Tier 4 emissions rated Caterpillar C7 diesel engine. Exceeds the current emissions requirements for industrial engines. Extensive use of manifold blocks in the hydraulic system to reduce the number of fittings and hoses, therefore reducing the number of potential leak points. Catchment trays with an accessible drain point incorporated into the control cabinet design. Hinged control panel mount to allow better operator visibility and moves the operator from close proximity to the potential danger areas of the drill.

Main Winch Travel limiting system to prevent overwinding the hoist plug. Wireline winch safety stop system to automatically stop the wireline winch when the over shot reaches a predetermined point. Rod Spin guard with rotation interlock to protect the drill crew from the spinning drill rod. Optional onboard Air Compressor with up to 1150/500 capacity.New Top Head Drive rotation head design, reduced noise at high speed, selectable high and low gears with a variable displacement hydraulic motor to allow a stepless speed control and adjustable rotation torque. A pressurised lubrication system is incorporated into the rotation head along with an external oil cooler and lube oil filter. A splined floating spindle with a 3 1/2" API IF Pin thread is used to drive the drill rods via a suitable adaptor sub.

The drill mast is a fabricated box section design providing a solid structure to withstand the operational forces while allowing a weight saving compared to other mast designs. A number of removable sections have been incorporated into the structure to allow good access for maintenance of the internal traverse system components.

- Features

New Top Head Drive rotation head design, reduced noise at high speed, selectable high and low gears with a variable displacement hydraulic motor to allow a stepless speed control and adjustable rotation torque. A pressurised lubrication system is incorporated into the rotation head along with an external oil cooler and lube oil filter. A splined floating spindle with a 3 1/2" API IF Pin thread is used to drive the drill rods via a suitable adaptor sub.

The drill mast is a fabricated box section design providing a solid structure to withstand the operational forces while allowing a weight saving compared to other mast designs. A number of removable sections have been incorporated into the structure to allow good access for maintenance of the internal traverse system components.

- Specifications

DEPTH CAPACITY

• NQ Core 1300 meters

• HQ Core 885 meters

• Open hole 3 1/2" rods: 380 meters

• RC 4 ½": 220 meters (nominal)

ENGINE

• Caterpillar C-7.1 Electronic 187kW (250Hp)

• Tier 3 Emissions Control

• 1800 RPM maximum engine speed

• Pump Drive Box

PULL BACK

• 115kN (25,853lbf) Actual

PULLDOWN

• 70 kN (15,736lbf)

TRAVERSE SPEED

• 60 m/min (196.8ft/min) Up

• 56 m/min (183.7ft/min) down

ROTATION HEAD

• Top Head Drive

• Maximum Torque 8087 Nm (6111 ft/lbf) in low gear

• 0 - 1500 Rpm speed range

• Two Speed Gearbox

• High Gear 3.04:1 & Low Gear 12.61:1 ratios

• Variable displacement 160cc hydraulic motor.

• Adjustable Rotation Torque control

• Infinitely variable rotation speed control

• Floating spindle 3 ½” API IF pin thread

• Pressure lube system with cooler and filter

MAIN WINCH

• 100kN (10,000kgf) maximum pull

• 120 M/min (393 ft/min)

• Mast Top Mounted

• Electronic Winch Travel limiter, fail to safe

• Main winch rope, safety factor to meet BS/EN791)

• Planetary reduction gear box & brake

• Variable Displacement hydraulic motor drive

WIRELINE WINCH

• Deck Mounted

• Maximum pull 15 kN (3,372ft/lbf)

• 1400 meters x 6mm rope

• Adjustable position Wireline spooler

• Speed up to 450 m/min (1476 ft/min)

• Adjustable pull limiter

• Safety stop system

• Wireline Depth counter as an option

WATER PUMP

• Standard FMC W1122BCD 140Lpm @1000Psi

• Option, FMC L11-18SC 265 Lpm @ 1800 Psi

FH2000

The FH2000 model shares many common components with the field proven FH3000, including rotation head, mast structure, head traverse system, control system and rod clamps.

- Specifications & Features

The FH2000 model shares many common components with the field proven FH3000, including rotation head, mast structure, head traverse system, control system and rod clamps. This modular design concept allows for increased operator familiarization with common user interface, reduced parts support inventory, ease of technical support through common hydraulic systems.

- Engineering Design

Experienced design engineers with many years drilling equipment experience. Designed to meet or exceed the relevant Australian and International Standards. Finite Element Analysis (FEA) of all components in the critical load path. Design verification via 3rd party design consultants. Designed to meet the requirements of MDG15 and MDG41.

- Safety & Environment

Latest generation Tier 4 emissions rated Caterpillar C7 diesel engine. Exceeds the current emissions requirements for industrial engines. Extensive use of manifold blocks in the hydraulic system to reduce the number of fittings and hoses, therefore reducing the number of potential leak points. Catchment trays with an accessible drain point incorporated into the control cabinet design. Hinged control panel mount to allow better operator visibility and moves the operator from close proximity to the potential danger areas oxf the drill.

Main Winch Travel limiting system to prevent overwinding the hoist plug. Wireline winch safety stop system to automatically stop the wireline winch when the over shot reaches a predetermined point. Rod Spin guard with rotation interlock to protect the drill crew from the spinning drill rod. Optional onboard Air Compressor with up to 1150/500 capacity.

- Features

New Rotation Head design, reduced noise at high speed, increased efficiency via a selectable planetary gear system, increased torque and horsepower to the drill rods, pressurized oil system for head lubrication and cooling. Increased drilling capacity through higher pull back and main winch performance. Similar size foot print to smaller capacity drills. Head racking system to allow full clearance for large diameter rods and casing handling. Improved Traverse cylinder design with easily replaceable gland seals. The gland seals can be replaced without removing the cylinder. Automatic traverse rope adjustment via take up cylinders. Modular design principles have been used with a focus on improved maintenance access and ease of component change out.

- Specifications

DEPTH CAPACITY

• NQ Core 2030 meters

• HQ Core 1377 meters

• Open hole 3 1/2" rods: 900 meters

• RC 4 ½": 600 meters (nominal)

ENGINE

• Cat C7.1 Electronic

• 205kW (275Hp)

• 1800 RPM maximum engine speed

PULL BACK

• 280kN (62900 lb/f) Limited Speed

• 244.8kN (55033 lb/f) Full Speed

PULLDOWN

• 115 kN (25853 lb/f)

TRAVERSE SPEED

• 50 m/min (164 ft/min) up

• 39 m/min (128 ft/min) down

MAIN WINCH

• 156kN (35048 lb/f) maximum pull 120 M/min (394 ft/min)

• Mast Top Mounted

• Electronic Winch Travel limiter, fail to safe

• 28mm main winch rope, safety factor 3.35:1 (exceeds BS/EN791)

• 1 x Bosch Rexroth A6VM160 variable displacement motors

• 1 x Brevini Planetary reduction gear boxes

• 1 x Multi disc brake units, fail safe spring activated, hydraulic pressure release

WIRELINE WINCH

• Mast Mounted

• 25 kN (5617 lb/f) Maximum pull

• 2100 meters x 8mm rope

• Adjustable position Wireline spooler

• Speed up to 450 m/min (1476 ft/min)

• Adjustable pull limiter

• Safety stop system

• Wireline Depth counter as an option

WATER PUMP

• Standard FMC W1122BCD 140Lpm @1000Psi

• Option, FMC L11-18SC 265 Lpm @ 1800 Psi

ROTATION HEAD

• Top Head Drive

• 14,324 Nm (10564 ft/lbf) in low gear

• 0 - 1500 Rpm speed range • High Gear 3:1 ratio

• Low Gear 19.57:1 ratio

• Bosch Rexroth A6VM160 Variable displacement motor

• Adjustable Rotation Torque control

• Infinitely variable rotation speed control

• Floating spindle 3 ½” API IF pin thread

• Pressure lubricated bearings and gears, with filtered and cooled lubrication oil system

FH3000

Latest generation Tier 4 emissions rated Cummins QSL 8.9 diesel engine. Exceeds the current emissions requirements for industrial engines. Extensive use of manifold blocks in the hydraulic system to reduce the number of fittings and hoses, therefore reducing the number of potential leak points.

- Engineering Design

Experienced design engineers with many years drilling equipment experience. Designed to meet or exceed the relevant Australian and International Standards Finite Element Analysis (FEA) of all components in the critical load path. Design verification via 3rd party design consultants. Designed to meet the requirements of MDG15 and MDG41

- Safety & Environment

Latest generation Tier 4 emissions rated Cummins QSL 8.9 diesel engine. Exceeds the current emissions requirements for industrial engines. Extensive use of manifold blocks in the hydraulic system to reduce the number of fittings and hoses, therefore reducing the number of potential leak points. Catchment trays with an accessible drain point incorporated into the control cabinet design. Hinged control panel mount to allow better operator visibility and moves the operator from close proximity to the potential danger areas of the drill.

Main Winch Travel limiting system to prevent overwinding the hoist plug. Wireline winch safety stop system to automatically stop the wireline winch when the over shot reaches a predetermined point. Rod Spin guard with rotation interlock to protect the drill crew from the spinning drill rod. Acoustic enclosure fitted around the rig engine and hydraulic system to reduce noise emissions.

- Features

New Rotation Head design, reduced noise at high speed, increased efficiency via a selectable planetary gear system, increased torque and horsepower to the drill rods, dry sump pressurized oil system for head lubrication and cooling. Increased drilling capacity through higher pull back and main winch performance. Similar size foot print to smaller capacity drills. Head racking system to allow full clearance for large diameter rods and casing handling. Improved Traverse cylinder design with easily replaceable gland seals. The gland seals can be replaced without removing the cylinder. Automatic traverse rope adjustment via take up cylinders. Modular design principles have been used with a focus on improved maintenance access and ease of component change out.

- Specifications

DEPTH CAPACITY

• NQ Core 2950 meters

• HQ Core 2000 meters

• Open hole 3 1/2" rods: 900 meters

• RC 4 ½": 600 meters (nominal)

ENGINE

• Cummins QSL Electronic

• 255kW (342Hp) @ 1800Rpm

PULL BACK

• 280kN (62900 lb/f) Limited Speed

• 244.8kN (55033 lb/f) Full Speed

PULLDOWN

• 115 kN (25853 lb/f)

TRAVERSE SPEED:

• 55.5 m/min (182 ft/min) maximum speed

WIRELINE WINCH

• 27 kN (6069 lb/f) Maximum pull

• Rope capacity 3000 meters x 8mm

• 450 meters/min Maximum Speed

WATER PUMP

• Standard FMC W1122BCD 140Lpm @1000Psi

• Optional FMC L11-18SC 265 Lpm @ 1800 Psi

ROTATION HEAD

• Top Head Drive

• 14,324 Nm (10564 ft/lbf) in low gear

• 0 - 1500 Rpm speed range

• 100% Theoretical

MAIN WINCH

• 226kN (50806 lb/f) maximum pull

• 100 M/min (328 ft/min) maximum speed

• 2 x Multi disc brake units, fail safe spring

activated, hydraulic pressure release.

• 9 meter rod pull capacity

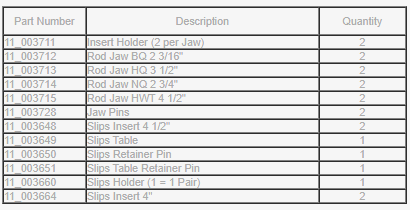

Rod Clamp

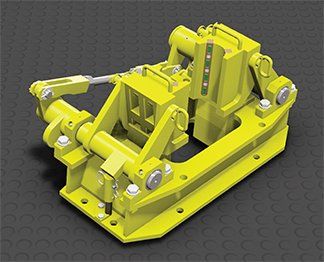

The Rod Clamp is a fabricated high tensile steel base frame for increased strength and lighter unitweight. It's body opens up to 225mm (8 3/4”) OD with high tensile fabricated lever arms.

- Rod Clamp Specifications & Features

• Fabricated High tensile steel base frame for increased strength and lighter unitweight.

• Body Opening up to 225mm (8 3/4”) OD.

• High tensile fabricated lever arms.

• Adjustable connecting with Left & Right hand threads allowing accurate adjustment of jaw actuation.

• Cast Jaw assemblies to suit most standard drill rod sizes.

• Light weight casting approximately 16kg per jaw.

• Easily replaceable Gripper Inserts for NQ & HQ jaw sizes.

• RC Slips Table, RC Slips holders and Inserts to suit 3 1/2”, 4” & 4 1/2” rod sizes.

• Changeable with industry standard rod clamps.

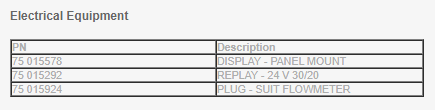

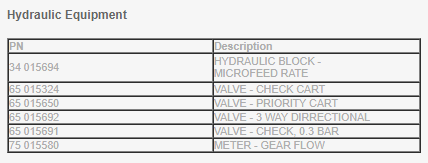

Sure Rate

The Evolution Drill Rigs (EDR) Penetration Rate Measuring System (EDR-SureRate) accurately measures and displays the relative penetration rate in real time. The system incorporates high quality instrumentation into a patented system designed to improve drilling efficiency.

- Specifications

The Evolution Drill Rigs (EDR) Penetration Rate Measuring System (EDR-Sure Rate) accurately measures and displays the relative penetration rate in real time. The system incorporates high quality instrumentation into a patented system designed to improve drilling efficiency.

- Accuracy

The EDR-Sure Rate is incorporated within the hydraulic actuated traverse cylinder circuit. In this circuit the bit weight is controlled by the hydraulic oil pulldown pressure, holdback pressure while the microfeed flowrate can be set by the EDR-Sure Rate to control the feed rate.

Between the normal operating range of 1 inch/minute and 4 inches/minute the relative error is less than 10% and improves as the penetration rate increases towards the maximum rate of 12 inches/minute.

- Equipment

The EDR-Sure Rate can be incorporated into most hydraulic operated drill rigs, including the Evolution FH3000, as an integral part of the control panel, electrical circuit and hydraulic circuits. The EDR-Sure Rate system can be used in either 12 or 24 Volt electrical systems.

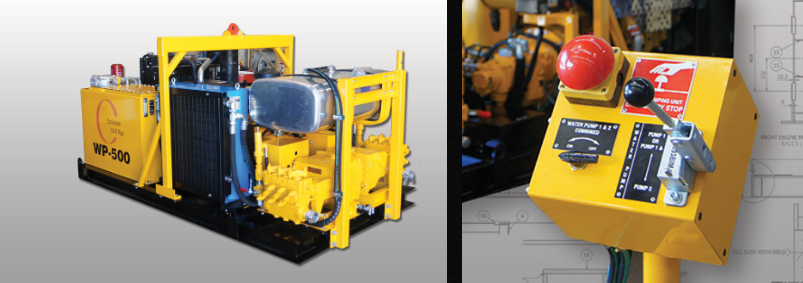

WP500 Mud Pump

The Evolution Drill Rigs WP500 Mud Pump offers a range of customer benefits for variety of applications.

- ENGINE

• Cummins QSB 4.5

• Tier 3 Emissions Control

• 119kW (160Hp) @ 2200 Rpm intermittent rating

• 2200 Rpm Maximum Speed

• Engine control panel on pump unit

• Engine shutdown system

• Radiator Cooler Pack with 500C ambient rating

• Heavy Duty Air cleaner with primary & secondary filter elements

- HYDRAULICS

• Pump Group Bosch Rexroth

• A11VO95/A10VO85/16

• Maximum circuit pressure 250Bar

• Hydraulic Oil capacity 400 litres

• Return Filter 10 micron

• Hydraulic Oil Cooler and fan

- WATER PUMPS

• 2 x FMC L11-18SC Water Pumps

• Water Flow range 0-530Lpm (140 US/Gpm)

• Maximum Water Pressure 69 Bar (1000PSI)

• Adjustable Water Pressure Relief Valves

• Water discharge pressure gauge

• Surge Chambers on suction & discharge

• Discharge Pulsation dampener

• Volvo fixed displacement piston drive motors

• Flex Drive Couplings

• 2" Water delivery hose x 10 meters long

- CONTROL PANEL

• Remote Pilot hydraulic control to attach at Rig Control Panel

• Selectable Pump 1, Pump 2 or both

• Adjustable friction lock control

• Selectable fine speed control on Pump 1

• Interconnecting hoses 10 meters long

- GENERAL

• Base Frame to support engine, pumps, hydraulic & fuel tanks etc

• Fuel Tank with 200 litres capacity

• Paint, Two Pack Evolution Yellow

• Estimated Weight 2890kg, excluding trailer

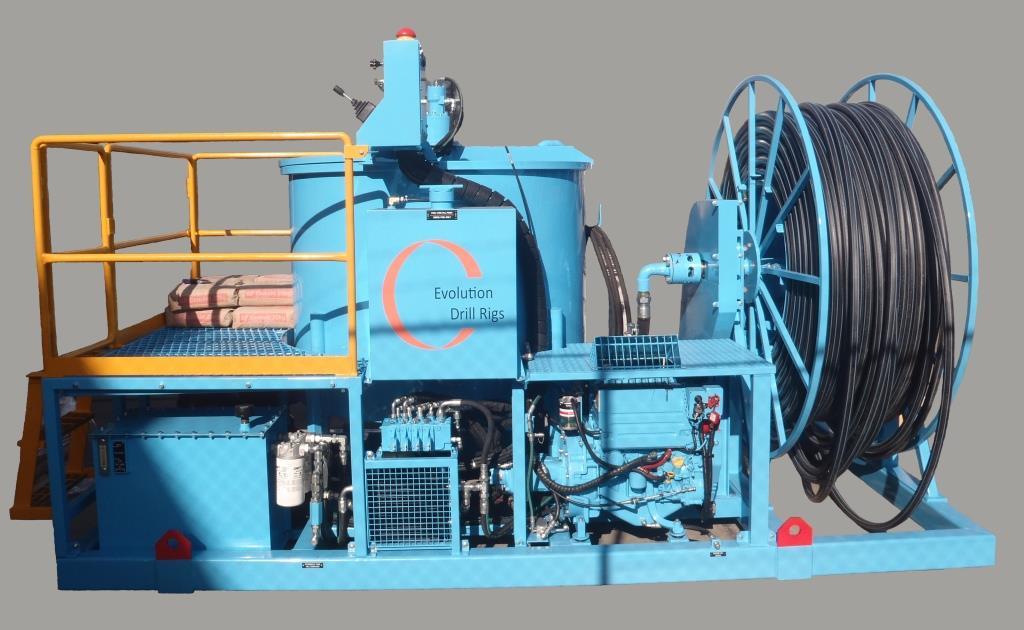

Grouting Unit

The Evolution Drill Rigs Gourting Unit offers a range of customer benefits with it's Bredel SPX 50 Pump, Brevini reduction gear box and many more features.

- ENGINE

• Detuz 3FL2011

• 28.5kW (38.3Hp) @ 2000 Rpm (continuous)

• 2200 Rpm Maximum Speed

• Engine control panel on pump unit

• Engine shutdown system

• Air Cooled

• Heavy Duty Air cleaner

- HYDRAULICS

• Pump Group Bosch Rexroth

• Main Pump A10VO45 Variable displacement

• Pilot Pump 5.5cc gear pump

• Maximum circuit pressure 160 Bar

• Hydraulic Oil capacity 100 litres

• Return Filter 10 micron

• Hydraulic Oil Cooler and fan

- GROUT PUMP

• Bredel SPX 50 Pump unit

• Brevini reduction gear box

• Brevini BR100NC hydraulic motor

• Slurry Flow range 0-85Lpm

• Maximum Pressure 15 Bar

• Adjustable speed control

- MIXING TANK:

• Tank capacity 1400 litres

• Hydraulic powered agitator

• Baffle plates inside the tank

• 3" outlet to slurry pump

• Grid on tank top for cement dispersion during mixing

• Sandblasted and painted with 2 pack paint.

- POLY REEL

• 600 meter capacity

• 40mm PN16 SDR11 Poly Pipe, Blue Stripe, 3.7mm wall

• Fabricated construction approximately 2.1 meters diameter

• Hydraulic Drive via reduction gearbox and chain & sprocket final drive.

• Adjustable speed control 1.5- 30 m/min

- CONTROL PLATFORM

• Mounted near mixing tank

• Engine controls, start, stop, throttle etc.

• Hydraulic controls for agitator, slurry pump and hose reel.

- GENERAL

• Base Frame to support all components, engine, pump, hydraulic & fuel tanks etc

• Fuel Tank with 60 litres capacity

• Access ladder to control platform

• Paint, Two Pack Evolution Yellow

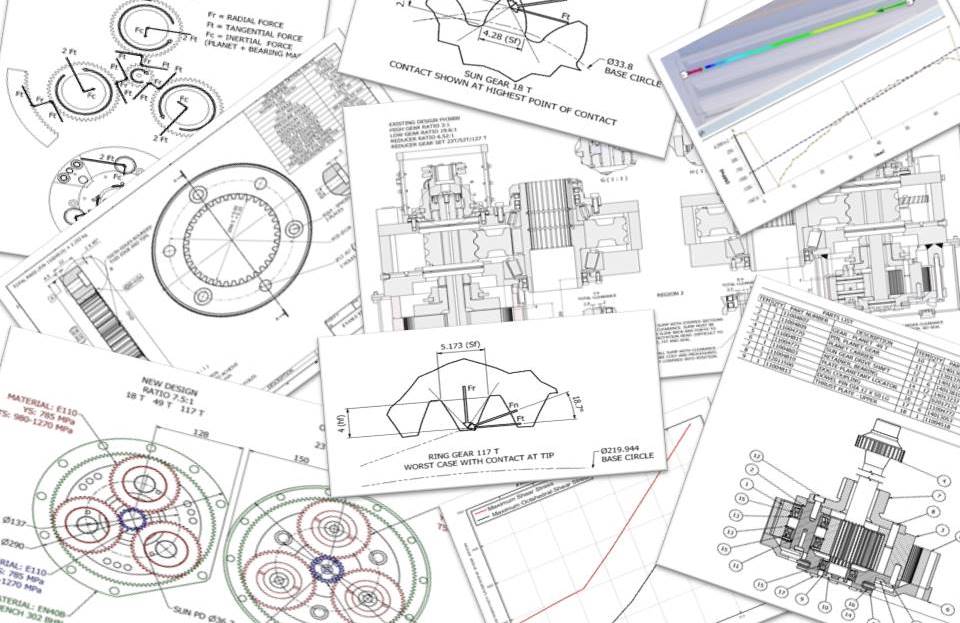

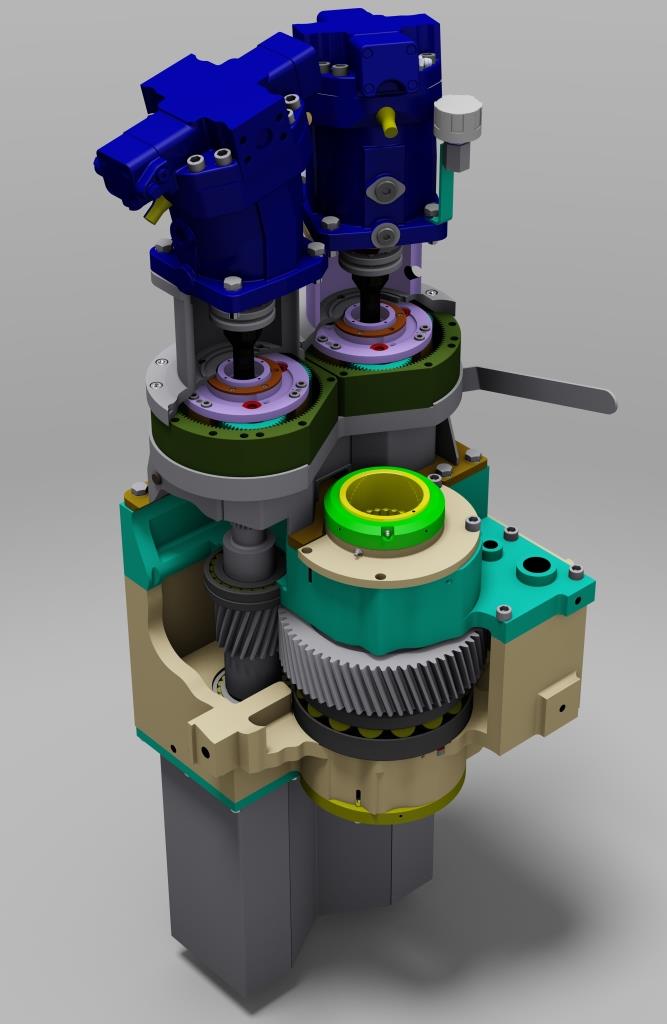

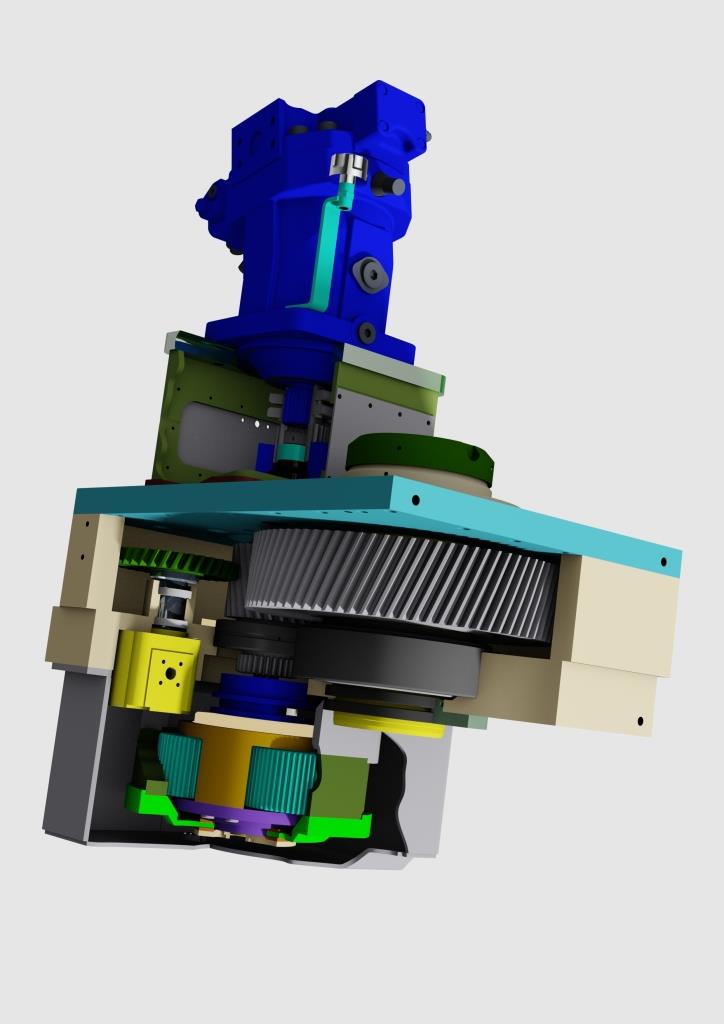

Custom Gearbox Range

Evolution Drill Rigs Gearboxes are custom in house designs. Designed with a life rating to AGMA or ISO standards, and using ANSYS simulation have been investigated for flexibility and strength. Choose from one of our existing gear boxes or have a custom build to suit your needs.

EDR Gearbox Range

Q280K

• Top Head Drive

• 0-28,000 Nm (20,651 ft/lbf) in low gear

• High Gear 3:1 Ratio

• Low Gear 22.5:1 Ratio

• Shift between high and low Gear Ratios

• 0-1500 Rpm Speed Range

• Splined Floating Spindle

• Independent pressurized lubrication system

• Gearbox oil level inspection windows

• Variable speed hydraulic motors

• Dual planetary gear set for high/low ratio

Q150K

• Top Head Drive

• 0-14,324 Nm (10,564 ft/lbf) in low gear

• High Gear 3:1 Ratio

• Low Gear 22.5:1 Ratio

• Shift between high and low Gear Ratios

• 0-1500 Rpm Speed Range

• Splined Floating Spindle

• Independent pressurized lubrication system

• Gearbox oil level inspection windows

• Variable speed hydraulic motor

• Planetary gear set for high/low ratio

Q80K

• Top Head Drive

• 0-8,328 Nm (6142 ft/lbf) in low gear

• High Gear 3.04:1 Ratio

• Low Gear 12.61:1 Ratio

• Shift between high and low Gear Ratios

• 0-1500 Rpm Speed Range

• Splined Floating Spindle

• Independent pressurized lubrication system

• Gearbox oil level inspection windows

• Variable speed hydraulic motor

• Gear train for high/low ratio